How is Climbing Carabiner Strength Tested? The Science Behind Your Safety

When you look at a carabiner and see engravings like "24 kN" or "8 kN," you're seeing the result of an intense, standardized, and destructive engineering process. These numbers are not just marketing; they are a promise of safety, born in testing laboratories where samples are pulled to destruction. Understanding how climbing carabiners are strength tested builds confidence in your equipment and underscores the critical importance of those tiny stamped numbers.

The "kN" Rating: A Unit of Force

Before diving into the tests, it's crucial to understand the unit: the kiloNewton (kN). Unlike kilograms, which measure mass, Newtons measure force. One kiloNewton is approximately 225 pounds of force. A 24 kN rating means the carabiner can theoretically withstand a force equivalent to holding about 5,400 pounds in a specific, ideal orientation. This unit is used because it accurately represents the dynamic forces of a fall.

The Testing Regimen: Three Crucial Tests

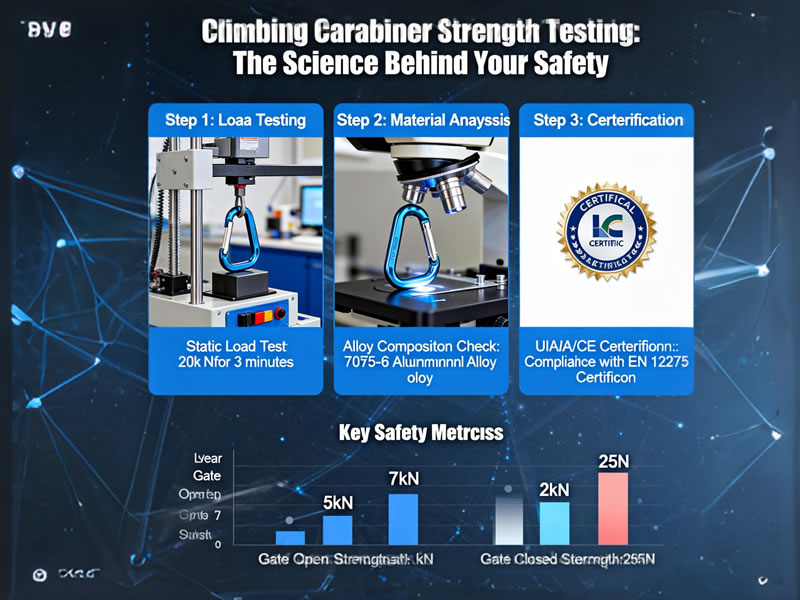

Carabiner testing is governed by strict international standards, primarily set by the UIAA (International Climbing and Mountaineering Federation) in Europe and CE (Conformité Européenne) certification. These standards mandate a series of tests that simulate real-world failure modes. Each test is performed on separate, brand-new carabiners until the unit fails.

1. The Major Axis Strength Test (The Benchmark)

This is the primary strength test and gives the carabiner its headline rating (e.g., 22 kN, 24 kN).

- Process: The carabiner is mounted in a specialized fixture on a hydraulic or servo-electric testing machine. The load is applied slowly and steadily along its longest dimension—from the spine to the opposite side of the gate.

- Failure Mode: The machine pulls until the carabiner permanently deforms (bends) or fractures. The maximum force recorded before failure is its major axis strength.

- Real-World Simulates: This is the intended loading direction, such as when you're hanging on a rope clipped through the carabiner.

2. The Minor Axis Strength Test (The Cross-Load Test)

This test identifies the carabiner's vulnerability to being loaded in its weakest direction.

- Process: The carabiner is loaded across its width, effectively pinching the spine and the gate together. A steel mandrel (a small, strong rod) is often placed inside to prevent the gate from bearing the load directly and to standardize the test.

- Failure Mode: The carabiner will typically bend open, or the gate and nose will fail. The strength here is typically only 25-33% of the major axis strength.

- Real-World Simulates: This mimics a dangerous "cross-loaded" situation, where a carabiner in a quickdraw is twisted against the rock.

3. The Open Gate Strength Test (The "What-If" Test)

This test evaluates the catastrophic weakening that occurs if the gate is prevented from closing.

- Process: The carabiner is loaded along the major axis, but with the gate held fully open. The gate is typically wedged open by a specified amount (e.g., 2-3mm as per UIAA standards).

- Failure Mode: The open gate creates a massive leverage point, causing failure at the nose. The strength in this configuration is also dramatically lower, often around 30% of the major axis strength.

- Real-World Simulates: This can happen if the carabiner's gate gets hooked on a rock edge or another piece of gear.

Beyond Destruction: The Quality Control Process

The destructive tests described above are performed on samples from a production batch. But what about every single carabiner that leaves the factory?

- Batch Testing: Manufacturers regularly pull samples from their production lines and destroy them to ensure the entire batch continues to meet the certified standards.

- Non-Destructive Testing (NDT): Every single carabiner undergoes a visual inspection and a simple but critical functional test. It is checked for smooth gate action and is often subjected to a "proof load"—a brief, high force (typically 2-4 kN) that should not cause any permanent deformation. This verifies the integrity of each unit without destroying it.

Conclusion: From Lab to Ledge

The strength ratings on your carabiner are the direct result of a rigorous, scientific, and destructive testing process designed to simulate worst-case scenarios. This process, governed by independent standards, ensures that the gear you trust with your life has a proven and quantifiable margin of safety. The next time you clip a carabiner, remember the immense force it withstood in a laboratory to earn its place on your harness. This knowledge isn't just technical—it's a foundation for confident and safe climbing.