Carabiner Hook with Swivel Function for Load Management

In the demanding fields of industrial rigging, rescue operations, and heavy lifting, managing forces is only half the battle. The other, often overlooked, challenge is managing rotation. A standard carabiner, when subjected to a twisting load, can transfer that torque into rigging slings, ropes, and the load itself, leading to dangerous and inefficient scenarios. This is where the carabiner with an integrated swivel function becomes an indispensable tool, transforming load management from a static connection into a dynamic, controlled system.

The Problem: Uncontrolled Rotation and Its Dangers

When a load spins or a rope twists under tension, a fixed carabiner acts as a pivot point, causing several critical issues:

- Rope and Sling Damage: The most immediate risk is the creation of destructive twists and kinks in synthetic slings, wire cables, and ropes. These kinks concentrate stress, significantly reducing the material's strength and leading to premature failure.

- Hockling: In wire rope, uncontrolled rotation can cause a severe failure known as "hockling," where the rope forms tight loops and literally collapses on itself, rendering it useless and dangerous.

- Gate Loading: Twisting forces can cause side-loading on the carabiner gate, placing stress on its weakest axis and potentially compromising its integrity.

- Unstable Loads: A spinning load is an uncontrolled load. It can become unstable during a lift, making precise placement difficult and increasing the risk of collision or dropping.

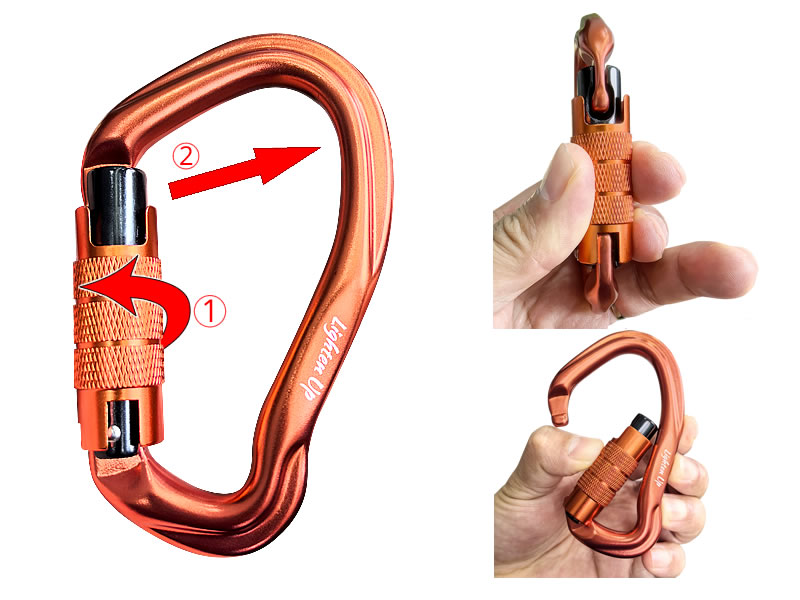

The Solution: How a Swivel Carabiner Works

A swivel carabiner is engineered with a high-precision bearing mechanism—typically using ball bearings or a robust bushing system—positioned between the carabiner's spine and its attachment point. This allows the body of the carabiner to rotate 360 degrees freely and independently, even under a full working load.

This simple yet brilliant function provides several key benefits for load management:

- Eliminates Torque Transfer: The swivel absorbs all rotational energy, preventing it from traveling up the rigging to the crane or down to the load. This keeps slings and ropes straight, untwisted, and in their strongest possible configuration.

- Enhances Safety and Control: By maintaining a tangle-free rigging system, the swivel carabiner drastically reduces the risk of kinks and hockling. This allows for safer, more predictable, and controlled lifts.

- Improves Efficiency: Crews spend less time untwisting lines and repositioning loads. The swivel enables smooth, continuous rotation for precise alignment and placement of materials.

- Extends Equipment Lifespan: By preventing the wear and tear caused by twisting and abrasion, a swivel carabiner significantly prolongs the service life of expensive slings, ropes, and other rigging hardware.

Applications and Selection Criteria

Swivel carabiners are not for every situation. Their weight and cost make them specialized tools for specific applications:

- Industrial Lifting: Essential for lifts with multi-leg slings where uneven tension can cause rotation, or when handling loads that are prone to spinning (e.g., long pipes, machinery).

- High-Angle Rescue: Allows rescuers to smoothly rotate a litter (stretcher) to navigate obstacles or keep a patient in a stable, comfortable position.

- Arboriculture: Helps manage the natural twisting of ropes during lowering of heavy limbs.

When selecting a swivel carabiner, prioritize these factors:

- Working Load Limit (WLL): Ensure the WLL matches or exceeds the demands of your lift, applying the appropriate safety factor (typically 5:1 for overhead lifting).

- Bearing Type: Ball bearing swivels offer smoother rotation under higher loads compared to bushing-based models.

- Material: Heavy-duty steel is standard for its strength and abrasion resistance.

- Certification: Look for markings certifying it to relevant standards (e.g., ASME B30.26).

In conclusion, a carabiner with a swivel function is far more than a connector; it is an active load management device. By effectively neutralizing the dangerous and inefficient effects of rotational force, it elevates the safety, control, and professionalism of any complex lifting or rigging operation. For any task where rotation is a factor, it is not just an accessory—it is a necessity.