Locking vs Non-Locking Carabiner: A Safety-Critical Distinction

Choosing between a locking and a non-locking carabiner is one of the most fundamental and consequential decisions in climbing, rigging, and any activity involving load-bearing connections. This choice is not about convenience but about managing risk. Understanding the precise mechanics, appropriate applications, and inherent limitations of each type is essential for building safe and efficient systems.

Core Mechanical Difference: The Gate

The defining difference lies in the gate's security mechanism.

- Non-Locking Carabiner: Features a simple, spring-loaded gate. Pressure on the gate's thumb tab compresses the spring and opens the gate; releasing it allows the spring to snap the gate shut. This design prioritizes speed and ease of use but provides no protection against accidental opening if the gate is knocked, snagged on rock or fabric, or experiences "gate flutter" during a dynamic load.

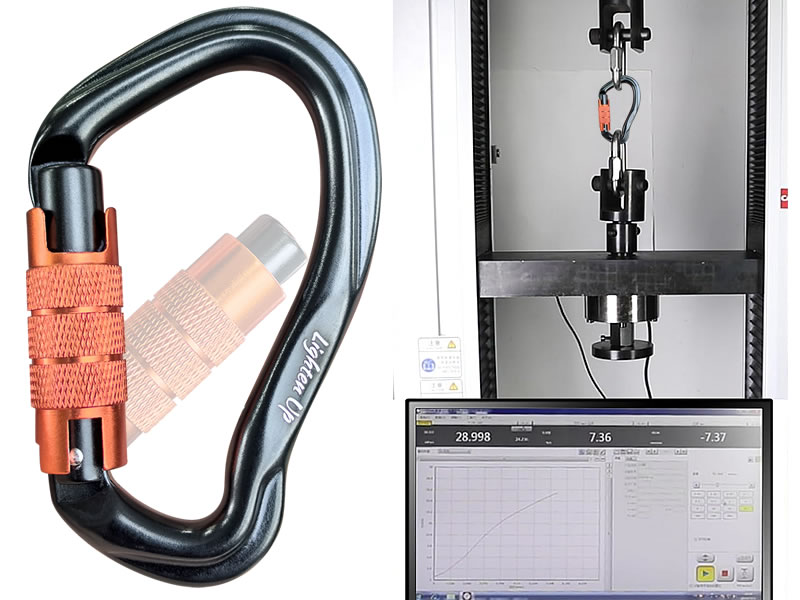

- Locking Carabiner: Incorporates a secondary mechanism that physically locks the gate in the closed position. Common types include:Screw-Gate: A threaded sleeve is manually screwed down over the gate.Auto-Locking (Twist-Lock/Triple-Action): The gate automatically locks when closed. Unlocking requires a specific, often multi-step sequence (e.g., twist then pull), making accidental opening highly unlikely.Magnetic Locking: Uses magnets to secure the gate, requiring a deliberate pull to open.

The Golden Rule of Application

Use a locking carabiner for any connection where an unintentional gate opening would result in a fall, serious injury, or catastrophic release of a load.

When a Locking Carabiner is Non-Negotiable (Life-Support):

- Personal Attachment Points: Connecting your harness directly to a belay/rappel device, an anchor, or a safety lanyard.

- Critical System Nodes: At the master point of an anchor, connecting two independent safety lines, or any point where a single failure would compromise the entire system.

- Industrial & Rescue Contexts: All primary connections in fall arrest, rope access, or technical rescue systems.

When a Non-Locking Carabiner is Appropriate (Non-Critical/Ancillary):

- Sport Climbing Quickdraws (Rope End): The action of clipping and unclipping the rope is fluid and requires a quick, snag-free gate.

- Gear Organization: Racking cams, nuts, and other equipment on your harness or gear sling.

- Accessory Attachment: Securing items like water bottles, backpacks, or tools where a detachment is merely an inconvenience, not a hazard.

Key Comparative Factors

| Factor | Non-Locking Carabiner | Locking Carabiner |

|---|---|---|

| Primary Design Goal | Speed, Efficiency, Light Weight | Security, Redundancy, Fail-Safety |

| Typical Strength | Equivalent major-axis strength (22-28 kN) | Equivalent major-axis strength (22-28 kN) |

| Gate Security | Low; vulnerable to accidental opening | High; designed to prevent accidental opening |

| Weight & Complexity | Lighter, simpler | Heavier, more complex mechanism |

| Operational Speed | Very fast, one-handed | Slower, requires deliberate action |

Critical Risks and Common Misconceptions

- The Substitution Error: The most dangerous mistake is using a non-locker in a life-support role. Never assume a "good clip" is enough.

- The "Finger-Tight" Fallacy: With screw-gate lockers, a sleeve that is not fully screwed down is effectively a non-locking carabiner. Always visually and physically check that the locking sleeve is fully engaged and flush.

- Cross-Loading is Not Solved by Locking: A locking mechanism does not compensate for a carabiner being loaded across its minor axis (sideways) or with the gate bearing load. These scenarios dramatically reduce strength regardless of gate type.

- False Security with Wear: Both types must be regularly inspected for gate wear, spring fatigue, cracks, and corrosion. A worn-out locking mechanism is unreliable.

Making the Right Choice: A Practical Framework

- Conduct a "What If?" Test: Before making any connection, ask: "What happens if this gate opens by itself right now?" If the answer involves a fall or injury, you need a locker.

- Build Redundant Habits: In your kit, use color-coding or dedicated locations for lockers vs. non-lockers. Develop a mandatory "lock check" routine.

- Match the Tool to the Task: For building a trad rack, you'll need many lightweight non-lockers for gear and a few robust lockers for anchors and belays. For a sport climbing quickdraw set, you'll use almost exclusively non-lockers, except for your belay device connection.

Conclusion

The distinction between locking and non-locking carabiners is a direct reflection of a fundamental safety hierarchy. Non-locking carabiners are superb tools for optimized performance in low-consequence scenarios. Locking carabiners are indispensable safety devices for managing high-consequence risks. Mastery lies not just in knowing the difference, but in cultivating the disciplined habit of applying the correct type for every single connection, every single time. This disciplined choice is the mark of a truly safety-conscious practitioner, where the integrity of a system always depends on its weakest link—and that link should never be an avoidable error in carabiner selection.