Carbon Fiber vs Aluminum Trekking Poles: Which Is More Durable? A Real-World Assessment

The debate between carbon fiber and aluminum trekking poles often centers on weight, but when it comes to durability, the answer is nuanced and highly dependent on the type of stress involved. Durability isn't a single metric; it's a combination of impact resistance, fatigue life, and failure mode. In a direct comparison, aluminum generally offers more forgiving and predictable durability for the average hiker, while carbon fiber excels in a specific strength-to-weight context but with a different risk profile.

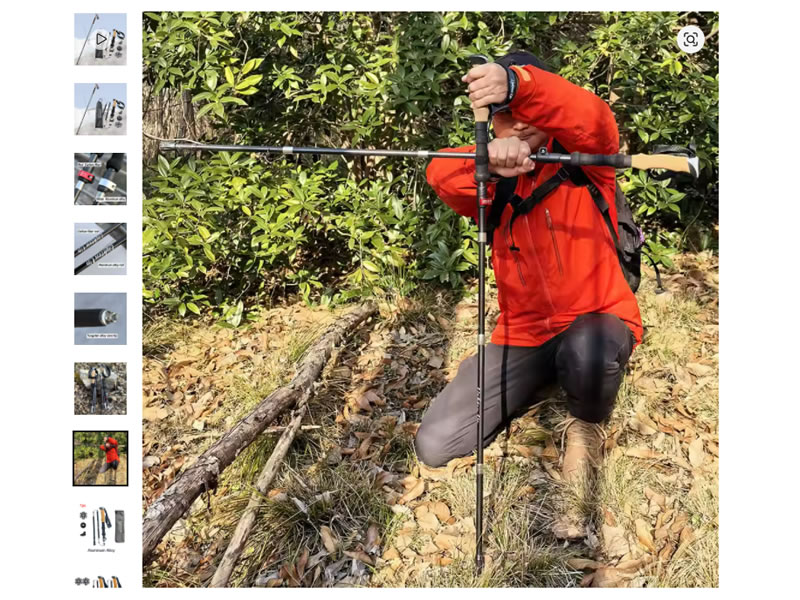

Buy Link: https://www.aliexpress.com/item/1005010715431647.html

Understanding the Materials

- Aluminum (6061 or 7075 Alloy): A ductile metal. When subjected to force beyond its yield strength, it bends or dents before breaking. This is a "forgiving" failure mode.

- Carbon Fiber: A composite material of carbon strands in a resin matrix. It is incredibly strong for its weight and stiff, but brittle. When it fails, it often does so catastrophically through cracking or splintering, sometimes without obvious prior warning.

The Durability Breakdown by Stress Type

1. Impact Resistance (The "Rock Strike" Test):

This is where aluminum shines. A sharp, lateral impact against a rock or a misstep that jams the pole into a crevice is the most common cause of field damage.

- Aluminum: Will likely dent or bend at the point of impact. It may remain usable (if awkwardly) to finish a hike. The damage is usually visible and progressive.

- Carbon Fiber: Risks a hidden crack or delamination in the resin matrix. It could fail suddenly later under normal load. While high-modulus carbon is very strong, a unlucky sharp impact in the wrong spot can cause immediate, irreparable failure.

2. Fatigue Life (Long-Term Flexing):

This concerns the material's resistance to weakening from repeated stress over thousands of steps.

- Both materials perform exceptionally well here when used within design limits. There is no evidence that one material fatigues significantly faster than the other under normal hiking loads. Quality poles from reputable brands are engineered to withstand millions of cycles.

3. Tensile & Compressive Strength (Weight-Bearing):

- Carbon Fiber: Has a superior strength-to-weight ratio. It can bear the same load as aluminum with less material, which is why it's lighter. For pure vertical loading (like supporting your weight on a descent), a well-constructed carbon pole is immensely strong.

- Aluminum: Has excellent and predictable strength, but requires more material to match carbon's stiffness, resulting in higher weight.

The Critical Factor: Failure Mode

This is the core of the durability debate.

- Aluminum Failure = Often Gradual & Manageable. A bent pole is inconvenient but rarely leaves you suddenly stranded. You can often straighten it roughly to get home.

- Carbon Fiber Failure = Often Sudden & Catastrophic. A cracked pole can collapse without warning, potentially leading to a fall. Repair in the field is nearly impossible.

Environmental & User Considerations

- Temperature: Aluminum becomes slightly stronger in cold weather but conducts heat/cold to the grip. Carbon fiber's properties are less affected by temperature, but the resin can become more brittle in extreme cold.

- Corrosion: Aluminum can corrode, especially in coastal environments, though anodization mitigates this. Carbon fiber is impervious to corrosion.

- User Behavior: A careful hiker on established trails presents minimal risk to carbon poles. A hiker who scrambles, bushwhacks, or frequently uses poles to vault over obstacles is subjecting them to high, unpredictable impacts better suited to aluminum.

Conclusion: Which Is More Durable For You?

The answer depends on your definition of "durable."

- Choose Aluminum Poles if your priority is impact-tolerant, predictable, and field-forgiving durability. They are the safer, more robust choice for: rugged off-trail use, backpacking with heavy loads, winter hiking (where ice and rock are hidden), beginners, or anyone who values gear that can survive rough handling and give warning before failing.

- Choose Carbon Fiber Poles if your priority is long-term durability under consistent, controlled loads with minimal weight. They are the efficient, high-performance choice for: weight-conscious thru-hikers, fastpackers, and those on maintained trails where sudden sharp impacts are less likely. You are trading some impact resilience for significant weight savings.

Final Verdict: For the broadest definition of durability encompassing resilience to mishandling and unpredictable trauma, aluminum is the more durable material. For durability defined as maintaining strength over time while minimizing system weight, carbon fiber is superior. Assess your typical terrain, hiking style, and risk tolerance to make the right call.