Creative usage of Climbing Swivel Ring: It's not just a connecting tool!

The purpose of the 30KN Climbing Swivel Ring is:

Rock climbing protection:

In rock climbing, a rotating ring is used to connect ropes and protective devices, reducing rope tangles and ensuring a smooth climbing process.

High altitude operations:

In high-altitude operations, the rotating ring can connect the safety belt and work rope, providing a flexible range of movement while ensuring safety.

Rescue operation:

In rescue scenarios, the rotating ring can quickly connect and adjust equipment, improving rescue efficiency.

Industrial applications:

In the industrial field, rotating rings are used for lifting, hoisting and other operations to withstand high-strength tensile forces.

In outdoor equipment, the selection of connectors directly affects safety and operational experience. What are the unique advantages of Climbing Swivel Ring compared to regular connectors?

1. Functional comparison:

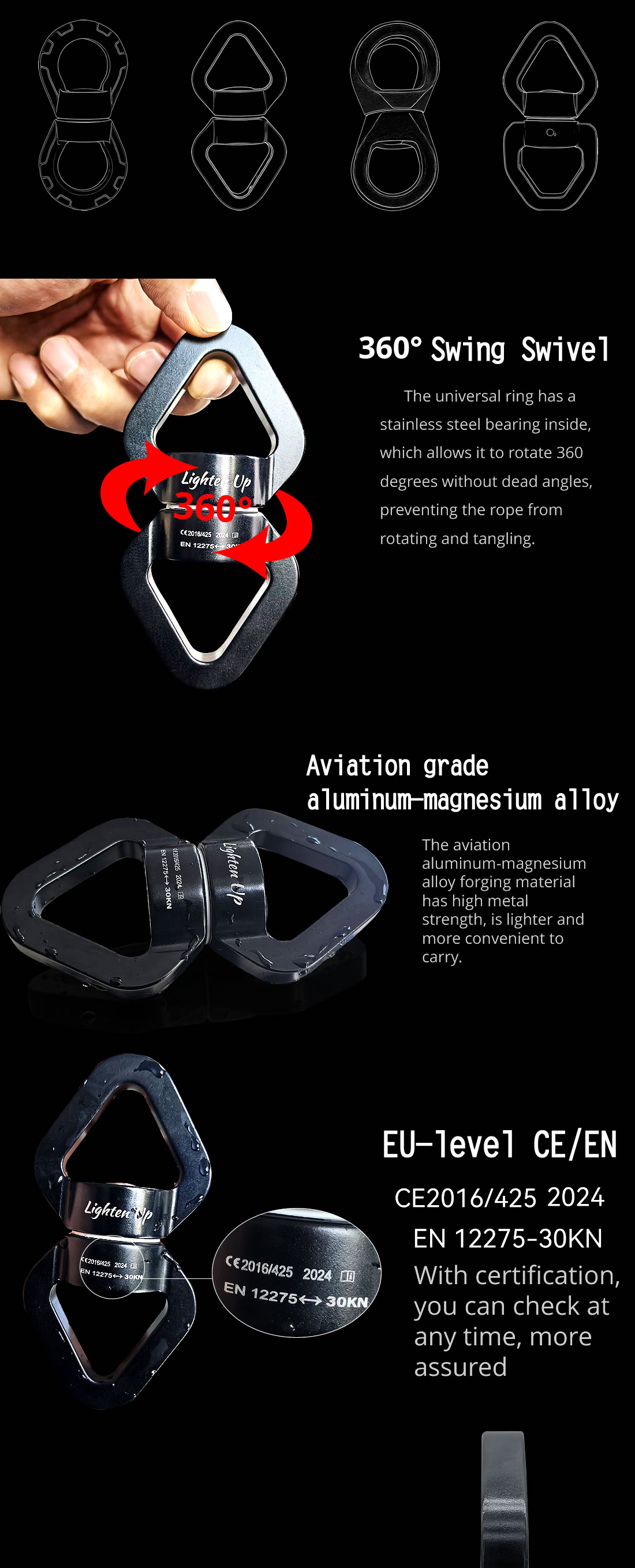

360 degree rotation design: reduces rope twisting, suitable for scenes that require frequent direction adjustment.

Ultra high load-bearing capacity: With a load-bearing capacity of 30KN, it is suitable for high-intensity operations.

Multi functional use: Suitable for various scenarios such as rock climbing, high-altitude operations, rescue, etc.

Ordinary connector:

Fixed design: unable to rotate, prone to rope twisting.

Limited load-bearing capacity: usually below 20KN, not suitable for high-intensity operations.

Single purpose: mainly used for simple connection tasks.

2. Safety comparison:

Climbing Swivel Ring:

Made of high-strength materials and rigorously tested to ensure safety in extreme environments.

Ordinary connector:

The material and design are relatively simple, and the safety is relatively low.

3. Comparison of applicable scenarios:

Climbing Swivel Ring:

Rock climbing, high-altitude operations, rescue, industrial lifting, etc.

Ordinary connector:

Simple outdoor activities or low-intensity assignments.

Advantages of the 30KN Climbing Swivel Ring:

Ultra high load-bearing capacity: A load-bearing capacity of 30KN (approximately 3000 kilograms) ensures safety in extreme environments.

360 degree rotation design: reduces rope twisting and improves operational flexibility.

Durable material: Made of high-strength alloy steel or stainless steel, corrosion-resistant and wear-resistant.

The 30KN rotary connector is an important equipment in outdoor and industrial fields, and proper maintenance can extend its service life and ensure safety. Here are some practical maintenance tips:

1. Regular inspection:

Before and after each use, check the connector for cracks, deformation, or wear.

Pay special attention to the flexibility of the rotating parts to ensure no lag.

2. Cleaning and maintenance:

Clean the connector with clean water and a soft cloth to remove sediment and dirt.

Avoid using chemical cleaning agents to prevent material damage.

3. Lubrication and maintenance:

Regularly apply a small amount of lubricating oil to the rotating parts to maintain their flexibility.

Use specialized lubricating oil and avoid using regular engine oil.

4. Proper storage:

Store the connector in a dry and ventilated place, avoiding humid environments.

Avoid prolonged exposure to sunlight to prevent material aging.

5. Avoid overloading:

Even if the load-bearing capacity of the connector is strong, overloading should be avoided.

Choose the appropriate connector based on the usage scenario to ensure safety.

Universal Rotating Connector is a multifunctional and high-performance connectivity device that can meet various needs in outdoor and industrial fields. If you need a reliable and flexible connector, this product is definitely worth considering.