The Science Behind 25KN Aviation Aluminum Carabiner Hooks: Strength and Safety Explained

The 25KN aviation aluminum hook and loop, with its excellent design and performance, has become an ideal choice for outdoor activities. The following is a detailed analysis of its design features, uses, and advantages:

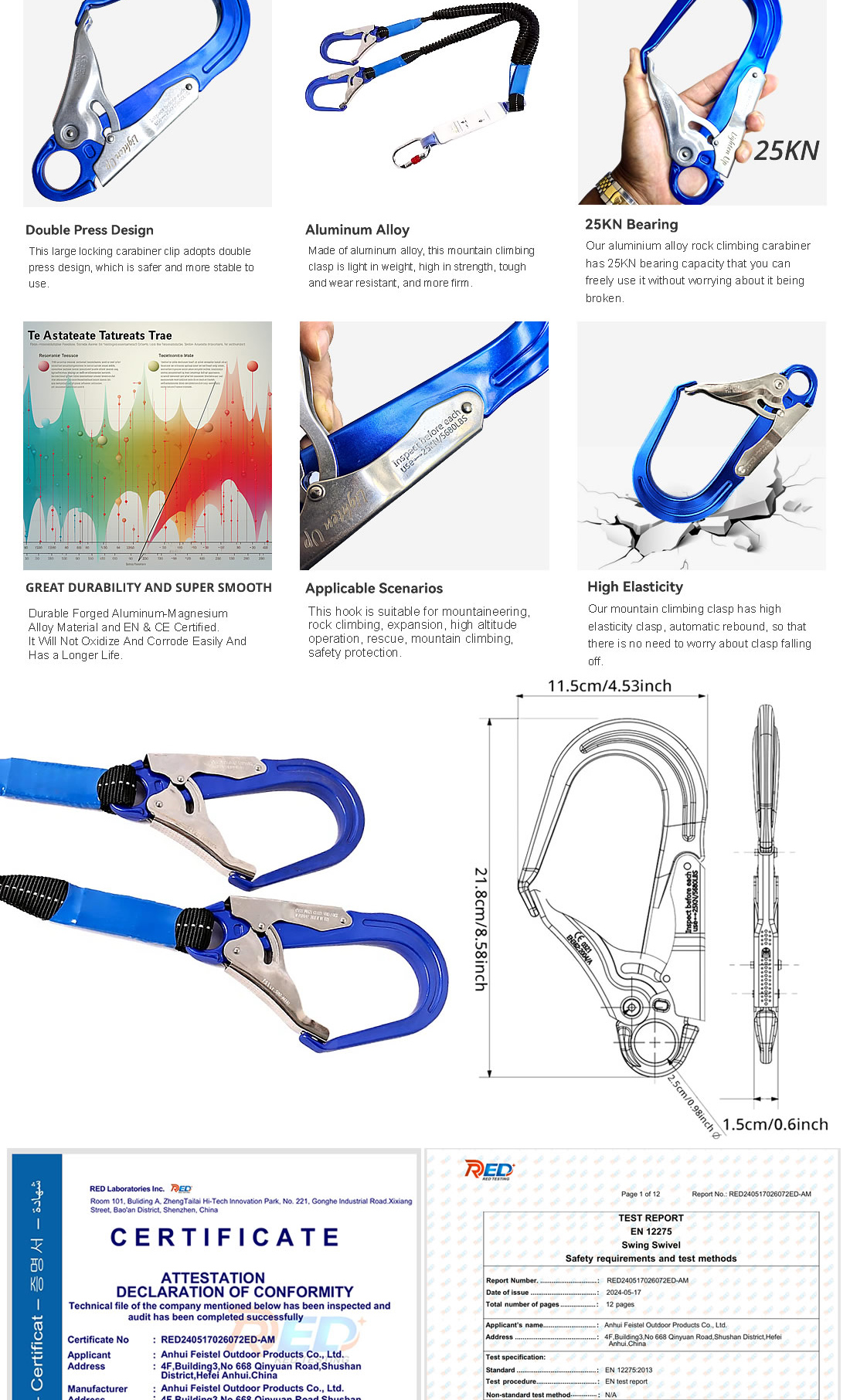

Design features:

High strength material:

Adopting aviation grade aluminum alloy, it combines lightweight and high-strength characteristics.

25KN load-bearing capacity:

A load-bearing capacity of 25KN (approximately 2500 kilograms) ensures safety in extreme environments.

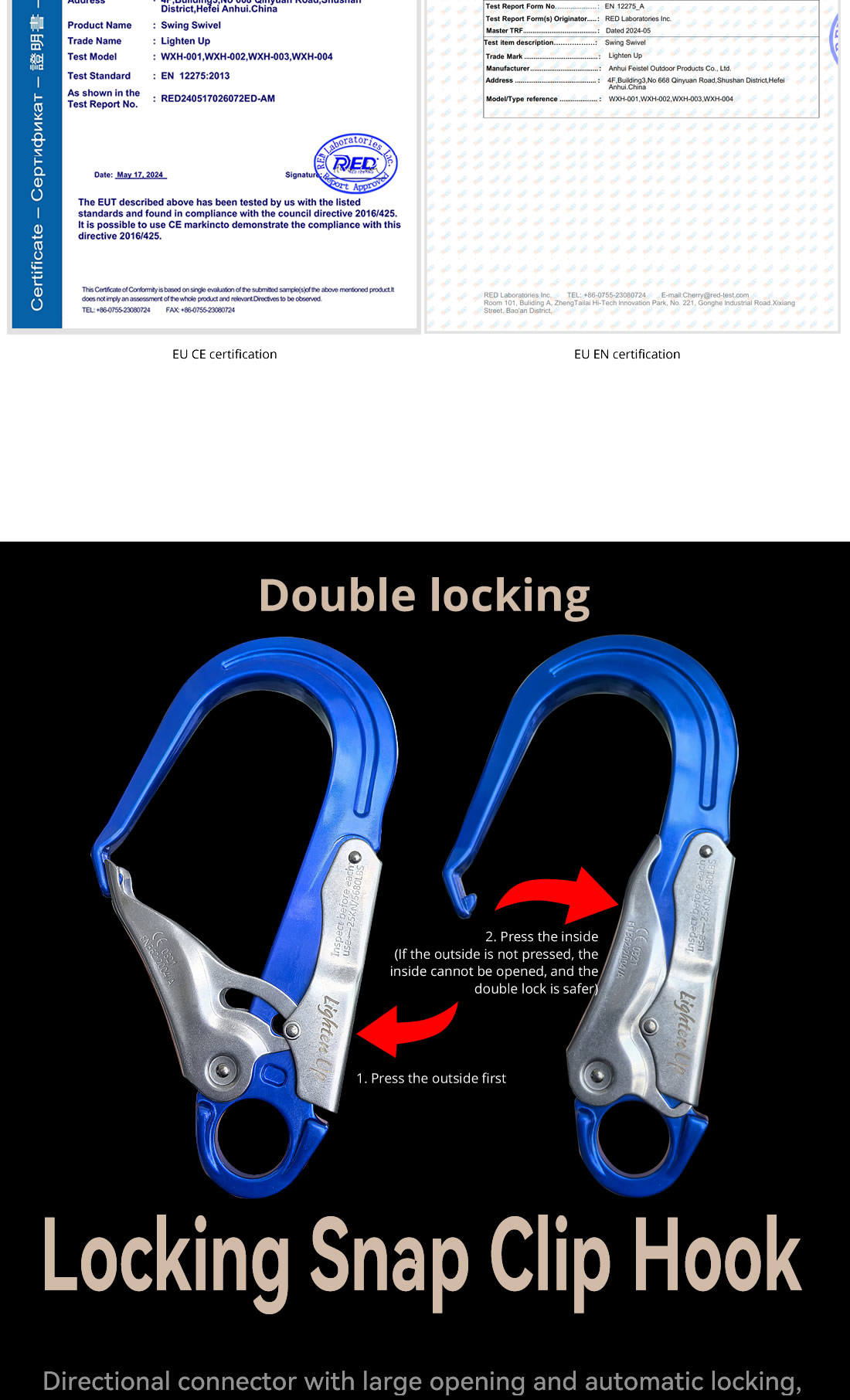

Lock door design:

Automatic or manual door locking design to prevent accidental opening and enhance safety.

Main purpose:

Rock climbing protection:

Used to connect ropes and protectors to ensure safety during the climbing process.

Mountaineering equipment connection:

Connect ice picks, ropes, and other equipment during mountain climbing to provide reliable support.

Rescue operation:

Quickly connect and adjust equipment in rescue scenarios to improve efficiency.

High altitude operations:

Used for industrial high-altitude operations, connecting safety belts and work ropes.

Advantages:

High security: 25KN load-bearing capacity and lock door design ensure safe use.

Lightweight: High strength materials reduce weight and are suitable for long-distance hiking and climbing.

Strong durability: corrosion-resistant, wear-resistant, suitable for various harsh environments.

The 25KN aviation aluminum hook and loop can play an important role in various outdoor scenarios. Here are its five major uses:

1. Rock climbing protection:

Used to connect ropes and protectors to ensure safety during the climbing process.

The D-shaped design reduces rope twisting and improves operational fluency.

2. Mountaineering equipment connection:

Connect ice picks, ropes, and other equipment during mountain climbing to provide reliable support.

The 25KN load-bearing capacity is suitable for dealing with complex terrain and extreme weather conditions.

3. Rescue operations:

Quickly connect and adjust equipment in rescue scenarios to improve efficiency.

High strength materials ensure reliability in emergency situations.

4. High altitude operations:

Used for industrial high-altitude operations, connecting safety belts and work ropes.

Lock the door design to prevent accidental opening and ensure safe operation.

5. Outdoor camping:

Used for setting up tents, hanging equipment, etc., to enhance camping convenience.

Lightweight design reduces weight and is suitable for long-distance travel.

Proper maintenance can extend the service life of 25KN aviation aluminum hooks and buckles, ensuring their performance and safety. Here are some practical maintenance tips:

1. Cleaning:

After each use, rinse the hook with clean water to remove sediment and dirt.

Wipe dry with a soft cloth to prevent moisture residue from causing rust or corrosion.

2. Inspection:

Regularly inspect the locking door, buckle body, and connection points of the hook and loop to ensure no damage or looseness.

Pay special attention to whether there are scratches or cracks on the surface of aviation aluminum materials.

3. Lubrication:

Apply a small amount of lubricating oil to the lock and moving parts to maintain their flexibility and smoothness.

Use specialized lubricating oil and avoid using regular engine oil.

4. Storage:

Store the hook and loop in a dry and ventilated place, avoiding humid environments.

Avoid prolonged exposure to sunlight to prevent material aging.

5. Avoid overloading:

Even if the hook and loop have strong load-bearing capacity, overloading should be avoided.

Choose the appropriate hook and loop according to the usage scenario to ensure safety.