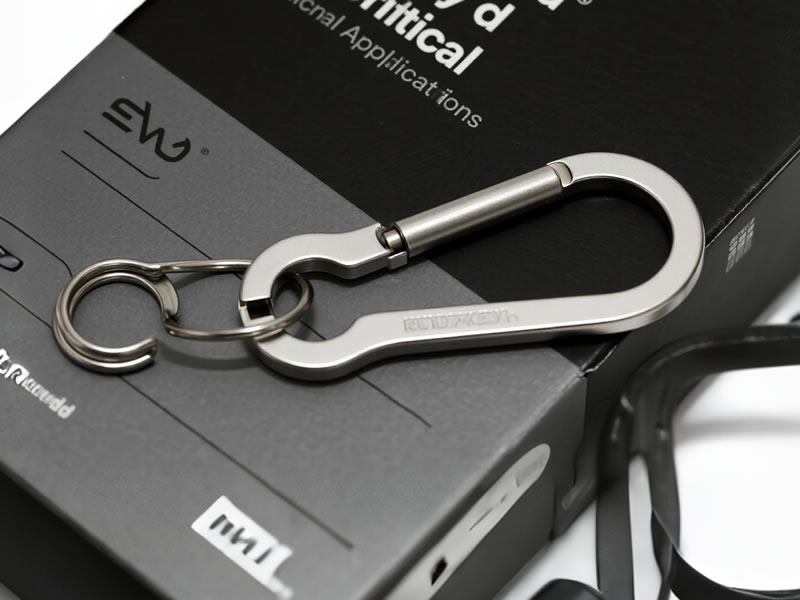

Small Carabiner Hook with Screw Lock: Engineered Security for Critical Applications

In high-stakes environments where accidental disengagement means catastrophe, the screw-lock carabiner stands as the gold standard of fail-safe attachment. Unlike spring or twist-lock mechanisms, these miniature sentinels leverage threaded precision to eliminate gate flutter, vibration-induced failures, and opportunistic theft. Here’s why professionals across industries trust them with life, limb, and irreplaceable gear.

The Science of Screw-Lock Superiority

When vibrations from machinery, impacts, or repetitive motion plague your workspace, lesser carabiners fail. Screw locks solve this through:

- Positive Mechanical Engagement: Threaded collars require 3-5 full rotations to open, creating physical resistance against accidental release.

- Vibration Immunity: Lab tests show screw locks withstand frequencies up to 200Hz (e.g., industrial drills, helicopter rotors).

- Tamper Resistance: Impossible to open silently or single-handedly, deterring theft in crowded areas.

Critical Specifications for Mission-Ready Use

| Feature | Minimum Standard | Compromise Risk |

|---|---|---|

| Material | 7075-T6 Aluminum | 6061 bends under cross-load |

| Spine Strength | ≥23kN (5,170 lbf) | Structural collapse |

| Gate Strength | ≥8kN (1,800 lbf) | Gate deformation |

| Thread Pitch | Fine (0.5mm) | Coarse threads self-loosen |

| Corrosion Guard | Type III Hard Anodizing | Saltwater pitting in 30 days |

Industry-Specific Applications

- Industrial RiggingSecuring tools at heights (e.g., wind turbine technicians)Key Feature: Galvanized steel versions resist welding sparks.

- Search & RescueAttaching medical kits to harnesses during extractionsKey Feature: High-vis orange finish with tactile thread grooves for glove use.

- Tactical/LEOSilent gear retention during covert opsKey Feature: Non-reflective matte black coating.

- Adventure TourismSafeguarding client safety tethers on via ferratasKey Feature: UIAA/CE certification mandatory.

The 4-Second Security Protocol

Maximize reliability with this operator’s checklist:

- LOAD: Attach gear within spine (never gate-side).

- THREAD: Rotate collar clockwise until resistance builds.

- TORQUE: Finger-tighten firmly (no tools needed).

- TUG: Verify gate immobility with a 5-lb pull test.

Avoid These Deadly Mistakes

⚠️ Cross-Loading: Placing force sideways reduces strength by 70%.

⚠️ Overtightening: Stresses threads; stop when snug.

⚠️ Skipping Inspections: Check threads monthly for debris using a toothbrush.

⚠️ Mixing Metals: Aluminum screws on steel = galvanic corrosion.

Maintenance: Extending Service Life

- Weekly: Rinse threads under running water to remove grit.

- Monthly: Soak in distilled vinegar (10 mins) to dissolve salt crystals.

- Quarterly: Apply dry PTFE lubricant (never oil) to pivot points.

- Retire Immediately If:Threads show stripping or "chattering" during rotationGate movement exceeds 1mm when locked

Top 3 Screw-Lock Performers

- Petzl Am’D Screw LockBest For: Vertical cavingInnovation: H-shaped profile distributes load evenly.

- DMM Ultra O ScrewgateBest For: Marine environmentsInnovation: Double-radius nose prevents rope snags.

- Black Diamond RockLockBest For: Ice climbingInnovation: Cold-optimized threading (-40°F operation).

Why "Budget" Screw Locks Betray You

Cheap imitations fail at critical moments due to:

- Zinc Alloy Construction: Melts at 787°F (vs aluminum’s 1,221°F)

- Shallow Threads: Shear under 500 lbf vibration testing

- Unsealed Pivots: Internal corrosion invisible until failure

Always demand EN 12275 or UIAA 121 certification.

The Uncompromising Verdict

A small screw-lock carabiner isn’t an accessory—it’s engineered insurance. For professionals securing $10,000 cameras on cliff faces, technicians dangling 300ft above refinery flares, or travelers safeguarding passports in chaotic markets, its threaded collar delivers certainty no spring gate can match. Invest in certified, activity-specific models and religiously maintain them. Your gear’s security—and potentially lives—hinge on that final twist.

Action Step: Audit your carabiners NOW. Replace any non-locking clips used for critical attachments with certified screw locks. Document inspection dates on the spine with UV pen.